As we enter a new era of technological advancements, the future of mining stands to benefit immensely from embracing digital twin technology. Digital twins in mining offer real-time insights, improved safety measures, and greater efficiency, positioning them to revolutionizing mining operations and contribute to the global energy transition.

This article will explore the key advantages of implementing digital twins in the mining sector, demonstrating how this innovative technology can optimize processes, reduce costs, and ensure the industry’s sustainable growth in a rapidly changing landscape.

What is a Digital Twin and How are They Created?

A digital twin is a virtual representation of a physical asset, system, or process that enables real-time performance monitoring, analysis, and optimizations. Digital twins are created by integrating data from various sources, such as sensors, IoT devices, and historical data, to develop a comprehensive, accurate physical object model. By creating a digital replica, organizations can gain valuable insights into the performance and efficiency of their assets, identify areas for improvement, and even predict potential issues before they occur.

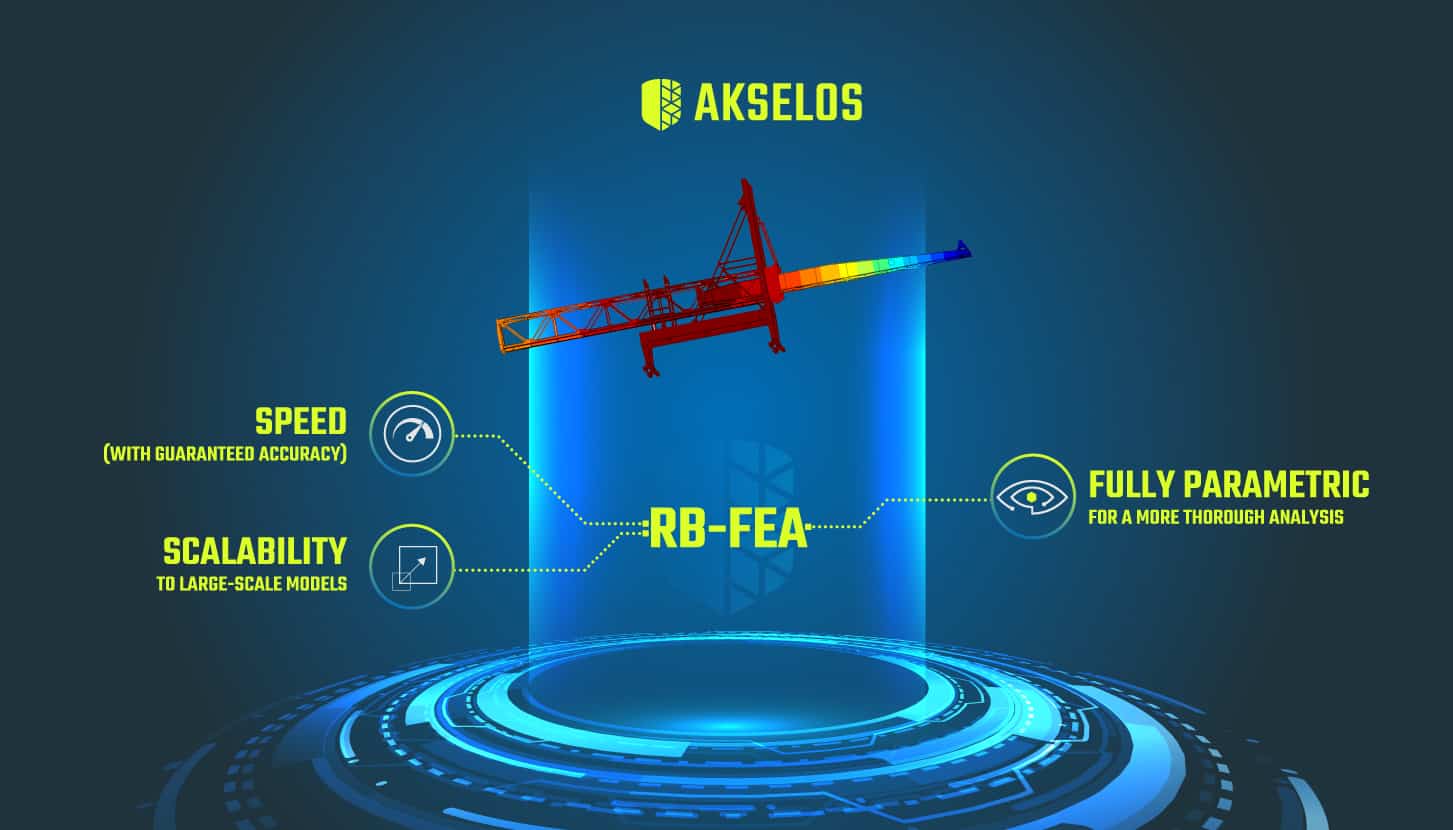

Akselos has developed structural digital twins powered by a new simulation technology called Reduced Basis Finite Element Analysis (RB-FEA). RB-FEA provides a holistic view of entire assets with unparalleled speed and accuracy. When used to create digital twins, RB-FEA allows operators to pinpoint critical safety issues down to the millimeter level and proactively fix problems before they escalate.

5 Benefits of Digital Twins in Mining

1. Visibility into the Remaining Asset Life of Critical Infrastructure

Digital twins can seamlessly integrate with advanced analytics and machine learning algorithms to forecast wear and tear, thereby providing a more accurate estimation of the remaining useful life of infrastructure components. This helps operators make informed decisions about when to repair, maintain, or replace assets, ensuring their operations’ continued efficiency and sustainability.

2. Hotspot Identification and Predictive Maintenance

Digital twins facilitate hotspot identification and predictive maintenance by monitoring equipment performance and detecting potential issues before they escalate into costly failures. This proactive approach reduces downtime, minimizes repair costs, and extends the life of critical assets.

For example, a common issue with mining excavators is the formation of cracks and other defects on the boom of mining excavators. With digital twins, operators can catch problems in advance, fixing them before they worsen and cause costly downtime. Such hotspot identification also helps identify potential safety hazards, enabling mining operators to implement preventive measures and maintain a safer working environment. Additionally, they can be used for training purposes, ensuring that employees are well-equipped to handle potential risks.

3. Downtime Reduction and Asset Life Extension

Identifying hotspots in advance and undertaking predictive maintenance is crucial for the future of mining as it reduces critical asset downtime. This brings significant financial benefits as, for example, the shutdown of a reclaimer can cost up to $1,000,000 a day in lost production.

Moreover, by identifying hotspots and reducing unplanned downtime, companies can defer significant capital investments associated with equipment replacement or upgrades, improving their financial performance and allowing for better allocation of resources.

4. Enhancing Safety and Reducing Risk

Safety is paramount for the future of mining, and digital twin technology can mitigate risks. The technology can help identify potential hazards and suggest preventive measures by providing real-time data and insights. This increased visibility into asset integrity ensures that mining professionals can maintain a safer work environment and reduce the likelihood of accidents.

5. Facilitating the Energy Transition by Increasing the Output of Raw Materials

The mining sector is crucial in the worldwide shift towards achieving net-zero emissions. The development of clean energy technologies necessitates large quantities of raw materials such as copper, iron ore, lithium, and nickel, all of which must be obtained from mining operations.

As we progress towards a net-zero future, the need for these essential minerals is projected to quadruple by 2040. The current mining capacity is insufficient to supply the required raw materials for this transition, and we need an additional 50 lithium, 60 nickel, and 17 cobalt mines by 2030. However, it takes an average of 16.5 years for a mine to advance from discovery to initial production, meaning that mining companies must get as much out of existing equipment as possible.

As discussed, digital twins can help mining companies increase output by optimising operations, identifying hotspots and extending the lifespan of critical assets, thus ensuring that the supply of these essential resources meets the growing demand.

The Future of Mining is Digital Twins

In conclusion, digital twin technology is poised to revolutionize the future of mining by optimizing operations, reducing costs, enhancing safety and contributing to the global energy transition. As mining companies strive to innovate and remain competitive, adopting digital twin technology will be essential for achieving sustainable growth and success in this rapidly changing landscape.

Take advantage of the opportunities that digital twin technology can bring to your organization. Take the first step towards harnessing the power of digital twins by speaking with one of our experts, who can guide you through the implementation process and help you unlock the full potential of this transformative technology.