In this detailed success story, we delve into the journey of a North American refinery grappling with a multi-million-dollar challenge in rotating equipment maintenance.

The refinery faced persistent problems with a Regeneration Blower, a critical piece of rotating equipment, which led to significant operational disruptions and financial losses.

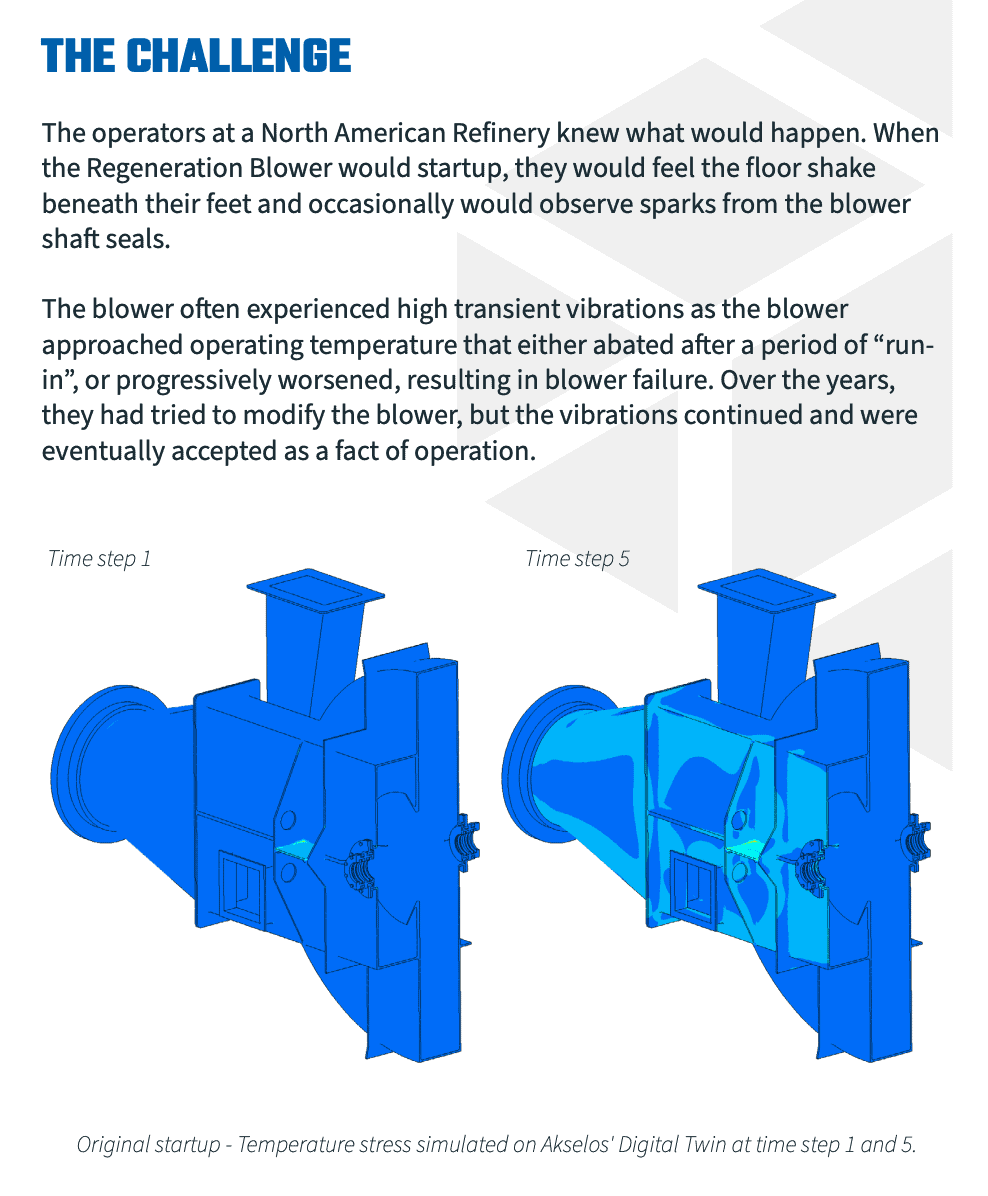

The engineers analyzed the entire system using Akselos’ digital twin technology. This approach was pivotal in identifying and addressing under-designed expansion joints, which were the root cause of excessive strain and vibration in the equipment.

Applying Akselos Structural Performance Management (SPM) software prevented costly premature failures of rotating equipment in oil and gas. It empowered the engineers with accurate structural intelligence for real-time decision-making.

The case study highlights the transformative impact of Akselos in rotating equipment maintenance, offering substantial cost savings and enhanced efficiency in operational processes.