By Amine Boumnijel – Offshore Structures SME & Product Owner, Akselos

Why Structural Integrity Needs to Evolve

The offshore industry is moving toward a more data-informed approach to integrity, although this shift is often described in broad terms. In practice, the change is driven by how inspection, maintenance, and repair are planned and justified based on actual structural condition.

Floating offshore structures operate in environments that change over time, and their structural behavior evolves with how they are loaded, maintained, and operated. Whether a unit is early in its service life, mid-life, or entering a life extension phase, operators are being asked to achieve higher levels of safety, uptime, maintenance efficiency, and carbon performance.

In this context, structural integrity is not only about demonstrating remaining life. It is also about how inspection, maintenance, and repair activities are prioritized and justified, so that effort and downtime are focused where they have the greatest structural effect.

The difficulty is that many integrity decisions are still guided by assumptions made during design or early operation, while the structure’s condition evolves in asset-specific ways. The key question becomes: how do we base integrity decisions on the structure as it behaves today, rather than on how it was expected to behave years earlier?

This leads to a key point: the design model is a starting condition, not a reliable representation of the structure throughout its life.

When Operating Reality Diverges from Design Assumptions

Design models assume standard loading patterns, wave climates, fatigue life estimates, and corrosion allowances. These assumptions are necessary for initial certification and early operation. But once an FPSO or FLNG unit enters service, its structural condition becomes specific to how it is actually operated.

- Tank loading and ballasting follow production reality, not the baseline patterns used during design.

- Fatigue develops based on the actual cyclic loading experienced in operation, which can differ significantly from design assumptions.

- The metocean environment over years of operation may not match the scatter diagrams or long-term conditions used in design studies.

- Corrosion and coating performance evolve differently compartment by compartment.

- Repairs, reinforcements, and structural modifications change local stiffness and load paths over time.

Because of these differences, the level of uncertainty grows as the structure moves away from its original design basis. In practice, this uncertainty is often addressed by adding layers of conservatism to inspection programs and maintenance planning. In some cases this leads to unnecessary effort; in others, it can leave critical priorities less visible because the operational reality diverges more than expected from the initial assumptions.

This has direct implications for inspection, maintenance, and repair planning. When integrity decisions continue to rely on original assumptions, inspection scopes tend to be broad in some areas and too limited in others. Repairs may be planned on a precautionary basis rather than on structural significance. Critical hotspots may be identified later than they could have been, increasing OPEX and the risk of unplanned intervention or downtime.

The issue is not lack of data. Operators collect extensive inspection records, tank loading histories, corrosion reports, and operational measurements. The challenge is that this information is rarely assembled in a way that provides a structural view of how the asset behaves today.

To improve the focus and efficiency of inspection and maintenance planning, the structural model needs to reflect current condition rather than remain fixed at the design basis.

Understanding the Structures as It Behaves Today

A continuously updated structural model reflects the current condition of the asset, rather than the assumptions made at the design stage. The idea is straightforward: as new information becomes available during operation, the structural model is adjusted so that it represents how the structure is behaving today.

This includes incorporating data such as thickness measurements and corrosion mapping, updated wave and motion information from in situ monitoring or wave radar, and tank loading and ballast history. Additional operational records can be reflected in the model where they have structural relevance, without requiring full detail to be modeled at all times.

The practical effect is a shift from reviewing data in isolation to understanding its structural significance. Instead of asking what has changed in the measurements, the discussion becomes: what does this change mean for stress distribution, fatigue usage, and prioritization of inspection or repair.

This direction is increasingly visible in the industry. Light Structures has demonstrated the value of continuous hull monitoring, Tampnet has improved offshore data availability, and Aker BP has emphasized shared situational awareness across decision makers. The underlying principle is the same: integrity decisions improve when the structural context is clear and current.

A model that evolves with the asset allows inspection, maintenance, and repair to be planned where they have the greatest effect. It allows emerging issues to be assessed earlier and with clearer justification, and it supports alignment between operations, integrity, and class.

This does not replace engineering judgment. It provides a more accurate basis for it.

Speed and Scale as Practical Enablers

For the structural model to support day-to-day integrity decisions, it needs to be both comprehensive and efficient to evaluate. The physics-based model must represent the structure as a whole, rather than only isolated sub-models, so that inspection and repair decisions reflect how different regions influence each other across the hull and topsides. Scale provides relevance.

It also needs to be solved quickly. If evaluating the model requires long analysis cycles, it becomes something that is consulted occasionally rather than actively used. The ability to run full-structure assessments in seconds makes it practical to update the model when new information becomes available and to compare options during planning discussions. Speed makes it usable.

This also enables integration with existing data sources and integrity systems. Thickness measurements and corrosion mapping, updated wave and motion data, and tank loading history can be incorporated without long turnaround times. The outputs from the model can then feed directly into inspection planning, repair prioritization, and fleet-level dashboards.

In practice, this allows structural insight to be available at the moment decisions are made, not after the fact. Data is not simply stored; it is converted into structural understanding that guides planning and reduces uncertainty.

See How Akselos empowered Shell to Cut a 6-month Workflow to 48 Hours

From Assumptions to Condition-Based Integrity and Life Extension

When the structural model reflects the current condition of the asset, inspection, maintenance, and repair activities can be planned based on structural significance rather than inherited assumptions. This allows effort and downtime to be focused where they have the greatest impact on reliability and availability.

Inspection can be directed to areas where fatigue usage or corrosion progression is meaningful, while scope is reduced where structural risk is low. Repairs can be scheduled at the appropriate time and scale, with some interventions safely deferred or bundled into planned campaigns. The workflow and documentation remain aligned with class requirements, ensuring decisions are both compliant and traceable.

This clarity also improves the handling of new findings. When corrosion, coating breakdown, denting, or crack indications are detected, their structural effect can be evaluated directly. The decision to monitor, repair, or reinforce is based on the condition of the structure, not precaution alone. This reduces reactive intervention and supports stable forward planning.

The same principle underpins life extension. When structural capacity and fatigue usage are evaluated using actual condition rather than broad design-phase assumptions, additional years of safe operation can be justified with evidence. Life extension becomes a clear, objective outcome of demonstrated integrity, rather than a conservative estimate.

Engineering judgment remains central. The difference is that it is supported by a structural model that represents how the asset behaves today, enabling confident, efficient, and well-justified decisions across inspection, repair, anomaly response, and life extension planning.

Watch how Akselos, Yinson Production, and Enauta are revolutionizing operations on the Atlanta FPSO

Moving From Assumptions to Understanding

The industry has relied on conservative assumptions for decades because we did not have a practical way to understand structural behavior as it evolves. That is no longer the case.

We can now base integrity decisions on the structure as it actually performs. We can focus inspection and repair where it matters. We can manage defects with clarity instead of urgency. And we can justify life extension with evidence instead of approximation.

The outcome is simple: safer operation, reduced downtime risk, and better use of maintenance and inspection effort. Engineering judgment does not disappear. It becomes stronger, faster, and better supported.

This is the new foundation for structural integrity.

Not assumptions.

Understanding.

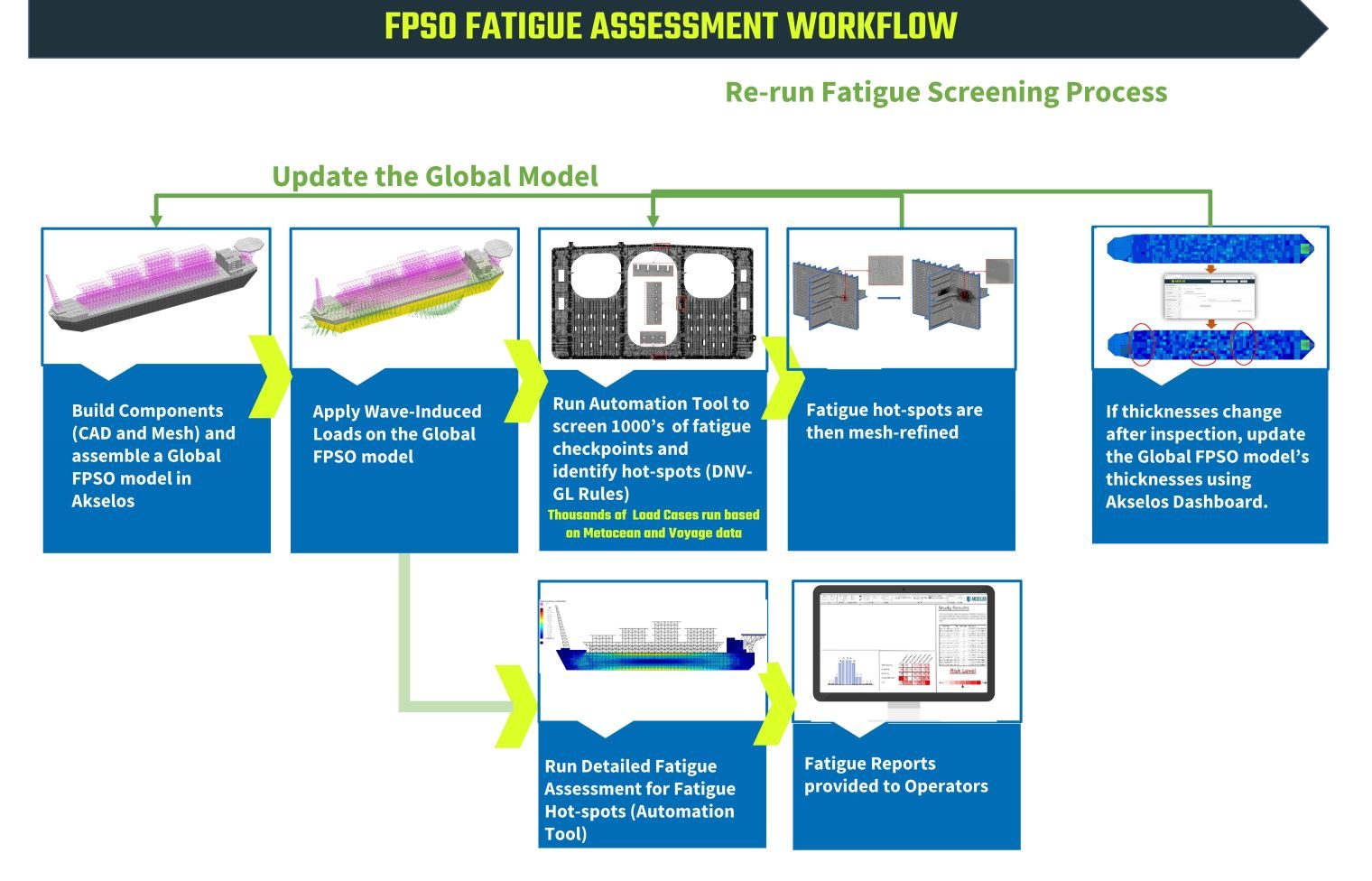

Read the Guide: How to Run Fatigue Assessment for FPSOs in 4 Steps