Predictive maintenance is crucial for oil and gas operations for preventing asset failures, reducing downtime and enhancing safety. By using data analytics and advanced technology to predict issues before they occur, companies can perform maintenance proactively, extending equipment lifespan and optimizing operational efficiency.

This approach not only minimizes costly unplanned shutdowns but also ensures compliance with stringent regulatory standards and improves worker safety.

Ongoing digital transformation within oil and gas operations will unlock the long-term benefits of predictive maintenance. Predictive maintenance uses data-driven techniques to predict and prevent failures, taking advantage of advancements in AI, advanced computational methods and digital twins. Predictive maintenance is a valuable investment; the long-term benefits of predictive maintenance, including cost savings and improved reliability, make it an essential strategy for maintaining a competitive edge in the industry.

What are operations in oil and gas?

Operations in the oil and gas industry describe all the activities required to bring crude oil and natural gas through the value chain, from exploration to its final refined form. These activities are classified into three general sectors: upstream, midstream and downstream:

- Upstream: At the very beginning of the value chain, oil and gas operations involve exploration, through geological surveys and exploratory drilling, and extraction.

- Midstream: Next, the raw material gets transported to its final refining sites.

- Downstream: Finally, downstream refineries produce the final marketable products, for consumer or industrial applications.

These operations require advanced technology to manage the complex processes involved in all the steps that exist across the oil and gas value chain.

Why predictive maintenance is needed in oil and gas operations

Maintenance approaches in the oil and gas industry have evolved over the years from reactive to preventive. The final step in this evolutionary journey is predictive maintenance, to ensure safety, efficiency and compliance on aging assets.

The oil and gas industry operates in diverse environments, from deep-sea drilling rigs to expansive onshore fields, all of which subject critical assets to extreme conditions. These conditions can accelerate wear and tear, leading to frequent breakdowns if not properly managed.

Maintenance in the oil and gas sector goes beyond ensuring operational efficiency; it also impacts safety, compliance and financial performance. As the oil and gas industry strives to gain the most value from existing assets, dedicated maintenance programs must aim to ensure safe operations for the longest time possible.

Enhance asset performance

Predicting the future behavior of an asset can enable operators to optimize production on the oil and gas site. By simulating the future state of an asset in response to various operating conditions and loads, operations teams can decide to open up operating windows when more throughput is needed in the field. Predictive maintenance provides the foundation for operations teams to understand how to fine-tune production without compromising asset health.

Ensure uninterrupted operations

The risk of asset failure has a wide-reaching impact in oil and gas operations. Ensuring that assets are maintained and functioning correctly is vital for the safety of workers and the environment. Downtime in oil and gas operations can be incredibly costly, leading to higher operational expenditure (OpEx). On one hand, an unplanned shutdown of a refinery can cost millions of dollars per day in lost production. On the other hand, even planned shutdowns can contribute to high OpEx when only time-based maintenance schedules are implemented. Efficient maintenance strategies are essential to minimize downtime, whether planned or unplanned.

Extend asset life

By identifying and addressing issues before they escalate, predictive maintenance can significantly extend the life of critical assets. By continuously monitoring equipment health using sensors and advanced analytics, predictive maintenance can detect early signs of wear and tear, corrosion, misalignment or other potential issues. Addressing these issues early prevents minor problems from escalating into major failures.

How traditional maintenance approaches affect oil and gas operations

Traditionally, maintenance in the oil and gas industry is performed on a time-based schedule, with a predetermined cadence of maintenance activities over the year. Even within an optimized, time-based maintenance scheme, breakdowns still occur, leading to unplanned downtime and relapse into reactive maintenance. Below is a breakdown of the two traditional maintenance approaches:

- Reactive maintenance: Reactive maintenance has continued to remain an unavoidable reality on the oil and gas site, going hand-in-hand with time-based maintenance schemes. Reactive maintenance approaches involve repairing or replacing assets only after they have failed. While simple, they often lead to further unexpected downtimes and higher long-term costs due to the extensive damage that asset failures can cause.

- Preventive maintenance: Preventive maintenance strategies, also known as time-based maintenance strategies, are based on performing maintenance activities at regular intervals, regardless of the asset’s condition. While a preventive maintenance strategy can help in reducing unexpected failures, the strategy can be inefficient and costly as it may lead to unnecessary maintenance activities, leading to over-maintenance.

Overall, assets in oil and gas terminals are especially subject to highly variable operating conditions. Environmental factors, varying loads and operational stress can cause wear and tear that does not align with fixed maintenance schedules, leading to both potential over-maintenance and missed failures.

Inevitably, reactive maintenance and preventive maintenance remain persistent complements to one another.

How does predictive maintenance work?

Predictive maintenance represents a significant advancement over the traditional maintenance approaches: reactive and proactive. By using data-driven techniques and advanced analytics, the predictive maintenance approach predicts equipment failures before they happen, allowing for timely intervention that is neither too early nor too late.

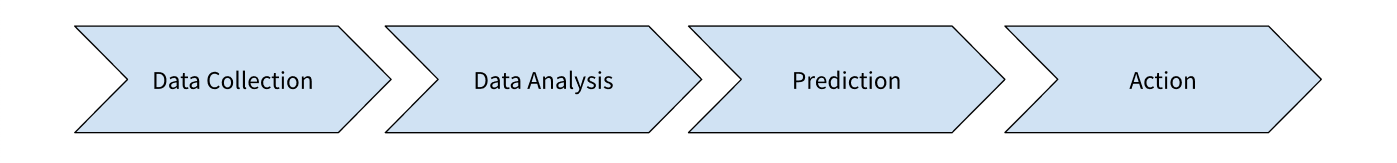

Predictive maintenance is a process that involves data collection and analysis, using much of the data that already exists on the oil and gas site. Then, the crucial prediction step enables operations teams to take targeted action:

- Data collection: The first step is to collect data. When using state-of-the-art software, historical datasets will provide an excellent foundation to the predictive capabilities of the system. As a next step, additional sensors and IoT devices may be installed on equipment to continuously collect additional data on various parameters such as temperature, vibration, pressure and operational speed.

- Data analysis: Next, data analysis is performed. Advanced analytics, machine learning and advanced computational algorithms analyze the collected data to identify patterns and anomalies that indicate potential equipment failures.

- Prediction: Then, centralized software makes the prediction of the asset’s future state known to everyone in the team. Using centralized software aligns all team members so that action can be coordinated and taken exactly when it is needed.

- Action: When the system detects a potential issue, the system alerts maintenance and operations teams, who can then take proactive measures to address the problem before it leads to a failure.

Additional benefits of predictive maintenance for oil and gas operations

The long-term savings of implementing predictive maintenance can be substantial, from reducing downtime to lowering maintenance costs. Additionally, safety and compliance are boosted through the data-driven process that underpins predictive maintenance software.

In addition to these primary benefits, predictive maintenance programs translate into more cost savings by optimizing the activities that are needed for overall asset integrity programs, through advanced structural simulations.

Maintain operational excellence

Safety on the oil and gas site is improved through better prediction of failure. By preventing asset failures that could lead to hazardous situations, predictive maintenance contributes to safer working environments and operations.

Software that enforces predictive maintenance with oil and gas operations can also ensure operations comply with industry standards, including API and ASME. Predictive maintenance software helps companies stay compliant with regulations by ensuring that assets are always in good working condition, thereby avoiding fines and legal consequences.

Governments and regulatory bodies impose strict regulations on the oil and gas industry to ensure safe and environmentally friendly operations. Non-compliance due to asset failure can result in hefty fines and legal consequences. Less straightforward is the damage to a company’s reputation when non-compliance leads to catastrophic consequences to people and the environment.

Even inventory management workflows become more efficient with predictive maintenance software. With better insights into what maintenance is needed and when, companies can optimize their spare parts inventory, reducing storage costs and ensuring the availability of critical components exactly on schedule.

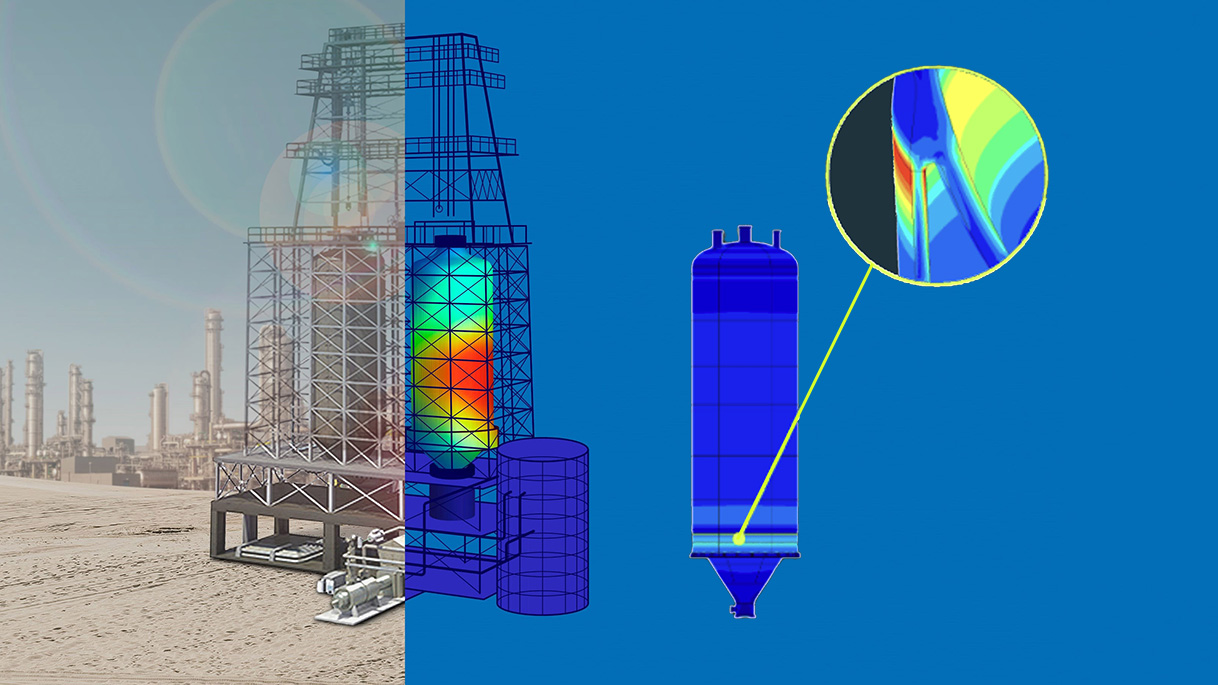

Discover critical hotspots through near real-time structural analysis

Predictive maintenance software that provides advanced structural analyses can uncover hotspots of stress within the largest structures of an oil and gas facility, in near real-time. By processing real-time and historical data from instrumented assets, operators can view the largest areas of vulnerability within an asset and then pinpoint exactly which operating conditions are causing the vulnerabilities. Continuous structural analysis of this kind is most useful for large structures whose inspection activities are complex.

Revolutionize asset integrity programs

By understanding the near real-time structural behavior of large assets through software with predictive capabilities, oil and gas operations teams can understand how best to continue modernizing its approach to asset integrity. Specialized insights into structural vulnerabilities within an asset clearly indicate when and where targeted integrity assessments will be needed.

With advanced software, historical datasets will already provide an outstanding foundation for assessing the structural integrity of an asset to a high level of detail. For organizations wishing to further digitalize their operations, software that can predict the structural health of an asset can further guide digitalization teams on which additional sensors can be placed on the asset. With a methodical approach to historical data management and instrumentation within an oil and gas site, asset integrity programs can achieve high levels of operational excellence.

Challenges in implementing predictive maintenance

Despite its numerous benefits, implementing predictive maintenance in the oil and gas industry is not without challenges. Typically, the initial investment, including the time and effort required, can be high. Without the correct software, the cost of installing sensors, acquiring data analytics tools and training personnel can be significant, posing a barrier for some companies.

The growing accumulation of data and pace of change within the IT ecosystem also requires specialized dedication. The vast amount of data generated by sensors can be overwhelming. Efficient data management and analysis systems are required to derive actionable insights. Meanwhile, integrating predictive maintenance solutions with existing legacy systems can be complex and requires careful planning and execution.

Finally, there is a need for a workforce skilled in both the operational aspects of oil and gas and the technical aspects of data analytics and predictive maintenance technologies. Attracting qualified talent to the industry can be a persistent challenge.

However, investing in state-of-the-art predictive maintenance software becomes an opportunity for oil and gas operations to attract a more digitally-savvy workforce. And with the right software, predictive analytics are successfully achieved with existing datasets. Advanced computational algorithms and simulations can leverage data from legacy systems and therefore reduce the barrier to entry to predictive maintenance programs.

The future of predictive maintenance

The future of predictive maintenance in the oil and gas industry looks promising, with continuous advancements in technology poised to overcome current challenges and further enhance its effectiveness.

As software capabilities continue to advance, operations teams will not need a mature condition monitoring program to initiate predictive maintenance programs. While improvements in IoT and data processing make real-time condition monitoring a reality for oil and gas plants, advanced simulation technology lowers the barrier to entry.

Integration with digital twins

Digital twins will revolutionize predictive maintenance by providing real-time, virtual replicas of physical assets. These digital models simulate the performance and conditions of equipment under various scenarios, enabling precise monitoring and analysis. By integrating IoT data, machine learning and advanced analytics, digital twins enhance predictive accuracy, identify potential issues early and optimize maintenance schedules.

This proactive approach minimizes downtime, reduces maintenance costs and extends equipment lifespan. Moreover, digital twins facilitate better decision-making, allowing maintenance teams to test solutions in the virtual environment before implementing them in the real world, ensuring more effective and efficient maintenance operations.

Physics-based models

For the largest assets on the oil and gas site, structural digital twins that are based on the laws of physics will provide asset integrity data to operations teams in near-real time, as an added benefit above standard digital twins. Also called physics-based models, structural digital twins will enhance predictive maintenance in oil and gas operations by simulating the physical behaviors and conditions of assets under various operational scenarios.

These models use fundamental principles of physics to predict wear, corrosion, fatigue and other degradation mechanisms. By integrating both historical data and real-time sensor data, physics-based models provide accurate predictions of asset failure and remaining useful life.

Digital transformation is a necessity for oil and gas operations

Predictive maintenance is not just a technological advancement; it is a strategic imperative for the oil and gas industry. By enabling proactive maintenance, reducing downtime, enhancing safety and optimizing costs, predictive maintenance ensures that oil and gas operations can continue to meet the world’s energy needs efficiently and safely, using existing infrastructure for as long as possible.

The long-term benefits make it a worthwhile investment for companies aiming to maintain a competitive edge in this critical sector. As technology continues to evolve, the potential for predictive maintenance to revolutionize the industry will only grow, paving the way for a more efficient and sustainable future.